The Future of PLC Programming: AI-Assisted Control Logic

Explore how artificial intelligence is revolutionizing the way engineers design and implement programmable logic controllers for complex industrial applications.

Industrial automation, control systems, and safety-critical engineering for theme parks, entertainment venues, and manufacturing facilities worldwide.

Trusted by Industry Leaders

End-to-end PLC programming, show control integration, and safety systems for dark rides, coasters, and interactive experiences. We engineer reliable systems that operate millions of cycles.

Integrated audio, video, lighting, and effects control for live shows, parades, and permanent installations. Precise timing synchronization across complex multi-venue environments.

High-speed conveyor systems, robotic pick-and-place, and intelligent sorting solutions. Designed for throughput, reliability, and seamless integration with existing operations.

Our systems don't just meet specifications—they transform operations.

"Dubs Controls delivered a control system that exceeded our safety requirements while maintaining show reliability. Zero unplanned downtime in 3 years."

"Their predictive maintenance system identified a critical failure 72 hours before it would have shut down our production line, saving us $2M in potential losses."

"The integration complexity was enormous—150+ show elements synchronized to millisecond precision. Dubs made it look easy."

Complete PLC and SCADA upgrade for a legacy dark ride attraction, improving reliability and enabling predictive maintenance.

Synchronized control of 200+ lighting fixtures, pyrotechnics, and audio systems for touring production show.

End-to-end automation of high-speed packaging line with vision inspection and real-time quality control.

Entertainment systems demand millisecond precision. Our integrated control solutions synchronize lighting, audio, video, and special effects to deliver flawless performances—every show, every time.

Professional audio distribution and processing

DMX and sACN control across venues

Pyro, fog, and special effects automation

Multi-screen synchronization and routing

Safety isn't an afterthought—it's engineered into every system from the ground up. Our predictive analytics and redundant architectures keep your operations running safely.

ML-powered analytics identify component degradation before failures occur, scheduling maintenance proactively.

24/7 system health dashboards with instant alerts for anomalies across all connected devices and networks.

Multi-layer E-stop networks, light curtains, and presence detection ensuring personnel safety at all times.

Hot-standby controllers, dual power supplies, and failover networks eliminate single points of failure.

Systems designed to NFPA 79, ISO 13849, and IEC 62443 cybersecurity standards from day one.

On-call engineering support with remote diagnostics and 4-hour on-site response SLA worldwide.

Over 25 years of operation across 500+ deployed systems

A proven 5-phase approach refined over 25 years and 500+ successful deployments.

Requirements analysis, site survey, and system architecture planning.

Detailed engineering drawings, control narratives, and safety analysis.

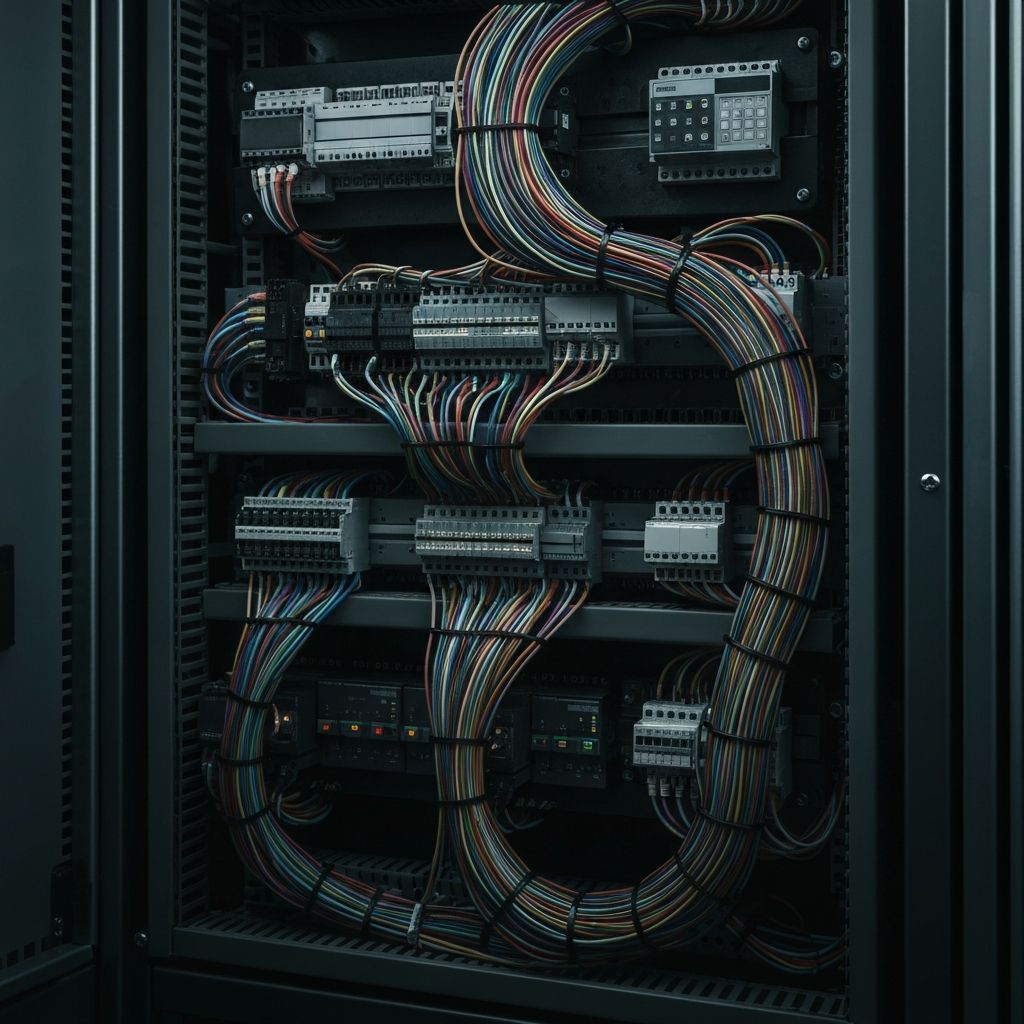

Panel fabrication, programming, and factory acceptance testing.

On-site installation, integration, and operator training.

24/7 monitoring, maintenance, and rapid response service.

Explore how artificial intelligence is revolutionizing the way engineers design and implement programmable logic controllers for complex industrial applications.

A comprehensive guide to IEC 61508, ISO 13849, and other essential safety standards for themed entertainment control systems.

Learn how to modernize outdated SCADA infrastructure while maintaining operational continuity and maximizing ROI.

Get answers to frequently asked questions about our engineering services, processes, and capabilities.

Whether you're upgrading legacy systems, building new attractions, or expanding manufacturing capacity—we're ready to engineer the solution.